Description

Purpose

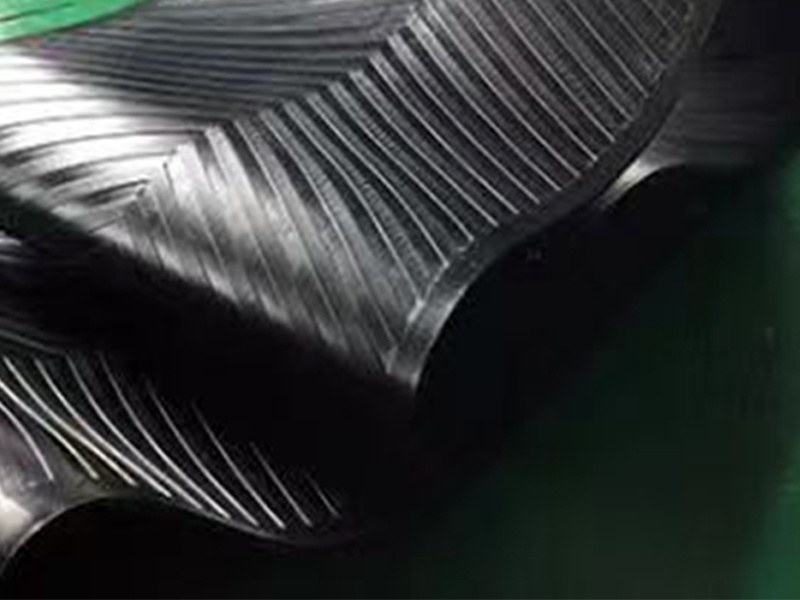

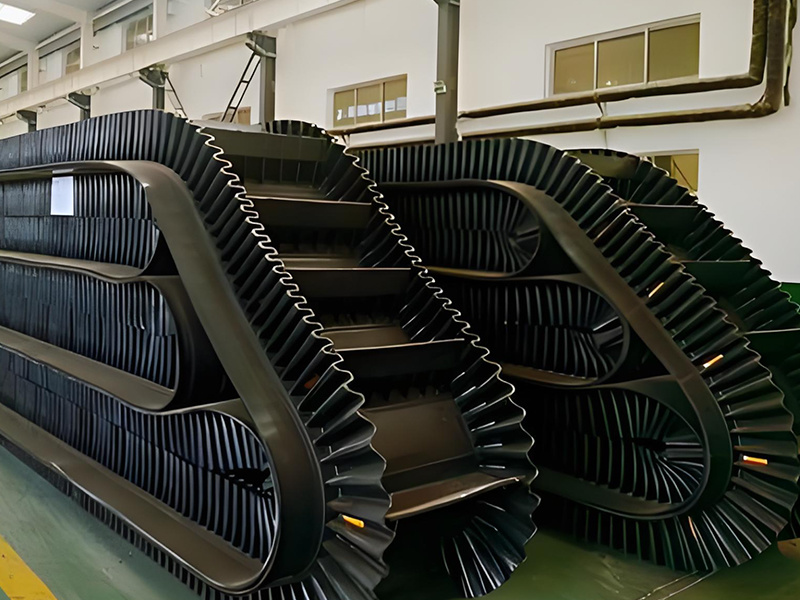

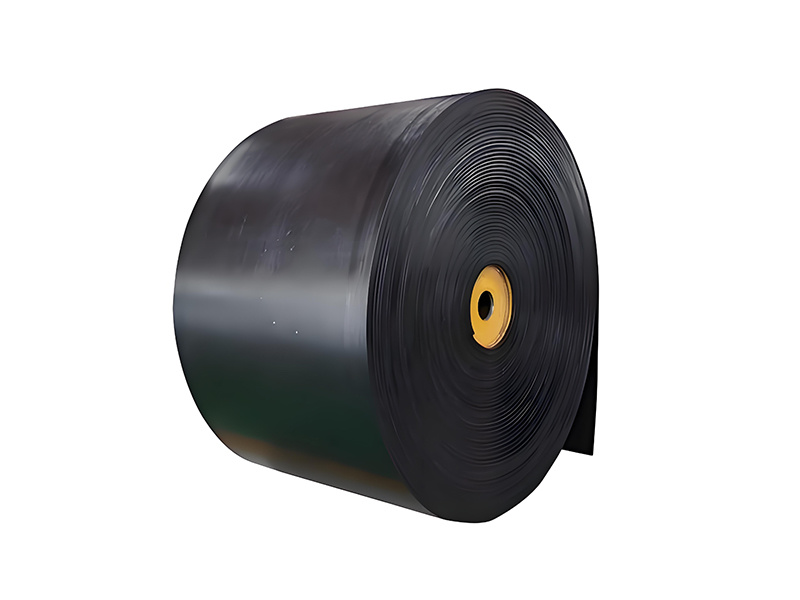

Heat-resistant conveyor belts are mainly used for conveying high-temperature materials, such as sintered hot coke, cement clinker, and hot castings. EPDM or SBR is used as the cover rubber depending on the main properties, damage conditions, loss of conveying capacity, and different heat resistance grades of the heat-resistant belt. High-strength, high-permeability polyester canvas or cotton canvas is used as the reinforcing layer. Heat-resistant glass cloth can be laid between the cover rubber and the carcass to improve the service life of the heat-resistant belt. It can be made into a circular belt according to customer requirements.

Heat-resistant and high-temperature conveyor belts are widely used in material conveying in coal, mining, port, metallurgy, power, and chemical industries.

Features

1. High strength, thin and lightweight.

2. Uses EP rubber-coated canvas as the carcass material.

3. The belt is soft, has a good trough shape, and good elasticity.

4. Impact resistant, wear-resistant, and corrosion-resistant.

5. Suitable for high-load, high-speed, and medium-to-long distance material conveying.

6. Stable operation, no deviation.

Specifications and Technical Parameters

| Specifications and Technical Parameters of Polyester Multi-layer Conveyor Belts | ||||||||||

| Fabric Type |

Fabric Structure | Fabric Type | Belt Thickness | Strength Series (N/mm) | Cover Rubber Thickness (mm) |

Width Range (mm) |

||||

| Warp | Weft | 2 layers | 3 layers | 4 floors | Upper Glue | Lower Glue | ||||

| Polyester (EP) |

Polyester | Cotton Nylon | EP-80 | 1.00 | 160 | 240 | 320 | 0-12 | 0-10 | 300-2500 |

| EP-100 | 1.00 | 200 | 300 | 400 | ||||||

| EP-125 | 1.05 | 250 | 375 | 500 | ||||||

| EP-150 | 1.10 | 300 | 450 | 600 | ||||||

| EP-170 | 1.10 | 340 | 510 | 680 | ||||||

| EP-200 | 1.20 | 400 | 600 | 800 | ||||||

| EP-250 | 1.40 | 500 | 750 | 1000 | ||||||

| EP-300 | 1.60 | 600 | 900 | 1200 | ||||||

| EP-350 | 1.70 | 1050 | 1400 | |||||||

| EP-400 | 1.90 | 1600 | ||||||||

| EP-500 | 2.10 | 2000 | ||||||||

Adhesion strength and elongation performance are shown in the table below.

| Adhesion Strength and Elongation Performance | |||||

| Belt Core Material |

Adhesive Strength | Elongation Performance | |||

| Interlayer N ≥ mm | Cover Layer and Layer N/mm |

Constant Elongation Strength | Constant Elongation Rate | ||

| Cover rubber thickness ≤1.5mm | Cover rubber thickness ≥1.5mm | ||||

| Polyester canvas | ≥ 5 | ≥4.5 | ≥ 5 | ≥ 10% | ≤ 4% |

The cover performance of the belt should meet the requirements of the table below.

| Belt Cover Performance | |||||

| Cover Grade | Tensile Strength | Elongation at Break | Abrasion Resistance | Change rate of tensile strength and elongation at break after aging | |

| Mpa | Kgf/cm2 | % | mm 3 | % | |

| H | 24 | 240 | 450 | 120 | -25~25 |

| D | 18 | 180 | 400 | 100 | -25~25 |

| L | 15 | 150 | 350 | 200 | -25~25 |

The physical and mechanical properties of the heat-resistant coating should meet the requirements of the table below after the heat-resistance test.

| Item | Model | ||||

| T1 | T2 | T3 | T4 | ||

| Range of Change | |||||

| Hardness | Difference between after and before aging | 20 | 20 | ±20 | ±20 |

| Larger value after aging | 85 | ||||

| Tensile Strength | Smaller value after aging | 12 | 10 | 5 | 5 |

| Performance change rate/% | -25 | -30 | -40 | -40 | |

| Elongation at Break | Performance change rate/% | -50 | -50 | -55 | -55 |

| Smaller value after aging | 200 | 200 | 180 | 180 | |

Specializing in the production of various conveyor belts, conveying machinery, and accessories, the company is committed to delivering efficient and reliable material handling solutions to global customers. Its products are widely used in industries such as metallurgy, mining, building materials, power generation, chemical, ports, and grain, helping enterprises achieve automated and intelligent production processes.

Customized Process

Order Notes

To meet diverse industry needs, our products are categorized into multiple specifications based on material handling requirements and operational environments:Standard, Heat-Resistant, Acid/Alkali-Resistant, Oil-Resistant, Cold-Resistant, and Flame-Retardant types.

Goods will be strictly tested before delivery, please check carefully after receiving the goods, if there is any problem, please contact us in time.

Online communication

Provide custom drawings

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt of goods

Successful transaction

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

What is the minimum order quantity?

It depends on the product.

Previous

High-temperature conveyor belt

You still doubt it? First get samples contact us!

subcategory

keyword

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!