Description

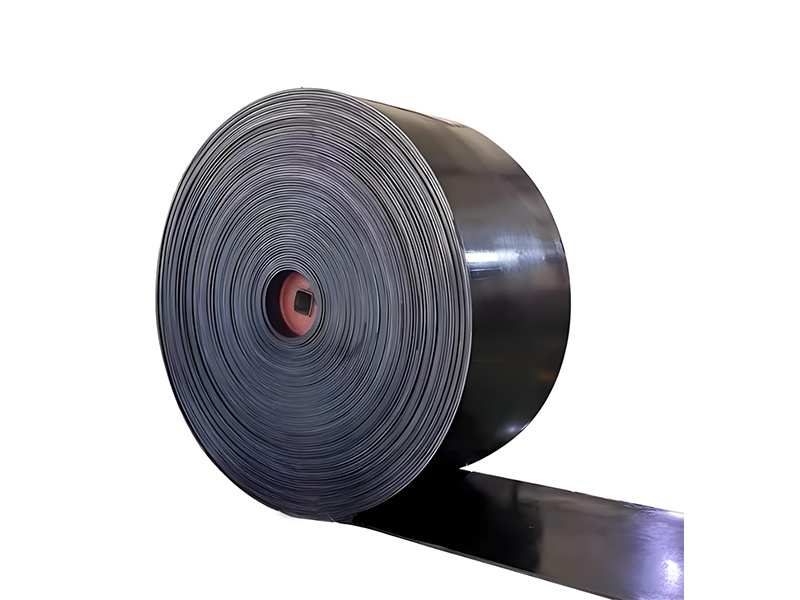

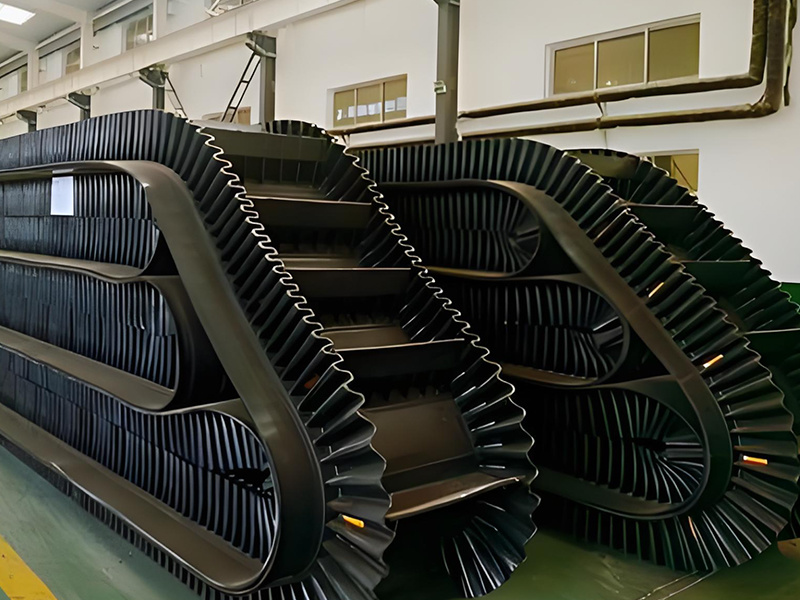

The overall core flame-retardant conveyor belt (PVC-PVG) is mainly used in underground coal mines. Features of this belt: the belt body does not delaminate, small elongation, impact resistance, and tear resistance. According to different structures, it can be divided into PVC type (plastic surface) and PVG type (rubber surface added on the basis of PVC) full-core flame-retardant belts, implementing the MT914-2002 standard.

(1) PVC flame-retardant conveyor belts are suitable for material conveying under dry conditions with an inclination angle of less than 16 degrees.

(2) PVG flame-retardant conveyor belts are suitable for conveying wet and watery materials with an inclination angle of less than 20 degrees.

1. Model N/mm (tensile strength) :

| Level | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 | Level 9 | Level 10 |

| Model | 680s | 800s | 1000s | 1250s | 1400s | 1600s | 1800s |

2. Flame retardant performance:

(1) Roller abrasion number: The surface temperature of the roller is not more than 325℃.

(2) Blowtorch burning: The average flameless time of the full-thickness specimen without a blowtorch is not more than 3.0S, and the average flameless time of the covering layer is not more than 5.0S.

(3) Propane burning: Undamaged length greater than 250mm

3. Surface resistivity:

The average value of the upper and lower surfaces is not more than 3.0 × 108Ω

4. Performance:

This conveyor belt has passed flame retardant tests and electrostatic tests and has obtained a qualified certificate, coal mine safety mark, and customer recognition.

5. Mechanical properties:

Excellent mechanical properties, providing users with a longer service life and economical installation and use.

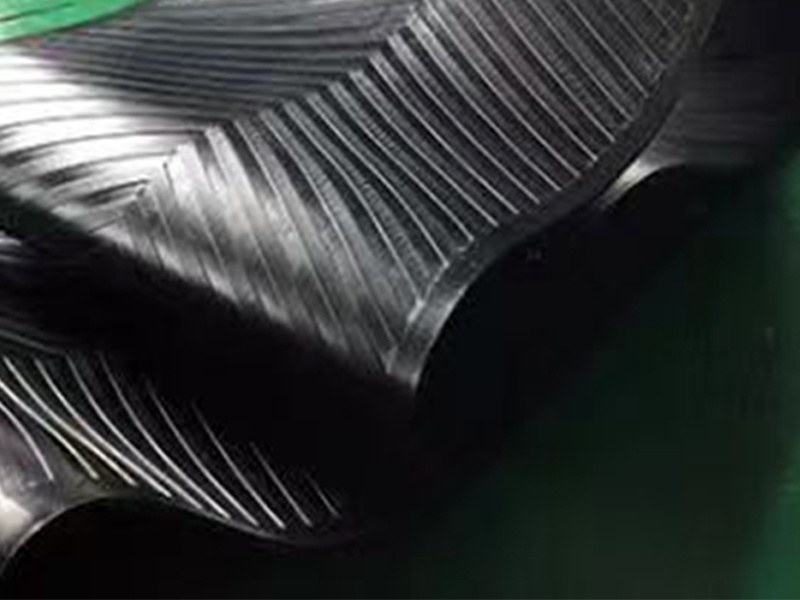

Service life: The service life of the belt is determined by the following factors: the warp and weft long filaments and the covering cotton are woven into a dense belt core; the specially formulated PVC material is used to immerse the belt core to achieve high bonding strength between the belt core and the cover rubber; specially formulated cover rubber; thus making the belt body impact-resistant, tear-resistant, and wear-resistant.

This product has excellent performance such as wear resistance, anti-static, waterproof, flame retardant, and high strength of the full-core flame-retardant belt, and it is more cost-effective and cheaper than other flame-retardant conveyor belts. It is one of the more common and popular flame-retardant conveyor belt varieties at home and abroad, especially suitable for conveying places with small slopes underground such as coal mines.

6. Product structure:

This product uses a whole core as the skeleton material, and it is made by impregnation and coating with PVC materials with anti-static and flame-retardant properties.

7. Joint performance:

According to the tensile strength of the belt body and the core structure, mechanical buckle connection is used, and its strength can reach 50%-100% of the tensile strength of the belt body; vulcanized joints are used, and their strength can reach 60%-100% of the belt strength. Various forms of joints can meet the different needs of customers and ensure the safe and efficient operation of the system.

| Average surface resistivity | ≤3×108Ω |

| Roller friction performance | The maximum allowable temperature ≤325℃, and no flaming or flameless combustion is required. |

| Alcohol blowtorch burning test | Average value ≤3S (with covering layer), single value ≤10S (with covering layer) Average value ≤5S (without covering layer), single value ≤15S (without covering layer) |

| Propane roadway combustion performance | Unburned retained segment length >250mm |

| High-energy roadway propane combustion test | Full-width undamaged length segment >2250 |

| Product specifications | Tensile strength (N/mm) | Elongation at break (%) | Tear strength (N) ≥ | ||

| Longitudinal ≥ | Transverse ≥ | Longitudinal ≥ | Transverse ≥ | ||

| 680S | 680 | 265 | 15 | 18 | 1090 |

| 800S | 800 | 280 | 15 | 18 | 1180 |

| 1000S | 1000 | 300 | 15 | 18 | 1180 |

Specializing in the production of various conveyor belts, conveying machinery, and accessories, the company is committed to delivering efficient and reliable material handling solutions to global customers. Its products are widely used in industries such as metallurgy, mining, building materials, power generation, chemical, ports, and grain, helping enterprises achieve automated and intelligent production processes.

Customized Process

Order Notes

To meet diverse industry needs, our products are categorized into multiple specifications based on material handling requirements and operational environments:Standard, Heat-Resistant, Acid/Alkali-Resistant, Oil-Resistant, Cold-Resistant, and Flame-Retardant types.

Goods will be strictly tested before delivery, please check carefully after receiving the goods, if there is any problem, please contact us in time.

Online communication

Provide custom drawings

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt of goods

Successful transaction

Can you accept small quantities?

Yes, accept small quantity, fast delivery

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

What is the minimum order quantity?

It depends on the product.

Flame-retardant conveyor belt

You still doubt it? First get samples contact us!

subcategory

keyword

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!